F-706 bulkhead parts 2h

2h

September 8, 2022

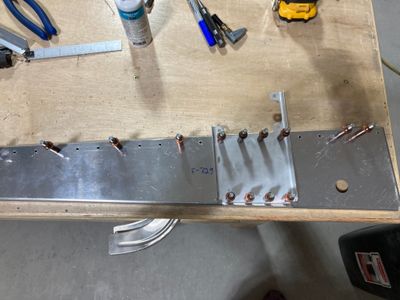

Today I worked on various parts of the F-706 bulkhead.

I got my aluminum angle from Aircraft Spruce, so I continued to work on the F-706 bulkhead. I wanted to make the F-729B angle just a bit longer, and I did not have enough material for the F-728B angle at all.

I started with fabricating the new F-729B angle and drilled it to the F-729A bellcrank rib. I also drilled the pitch servo bracket at this time. I don't have the autopilot servo (I am going with Garmin's GSA 28), but seems to be the right location (as per the G3X installation manual).

Then I had some concerns about the alignment of the hole on the F-729C angle to the F-729B angle since some movement is possible between these two parts. Since the hole was drilled already (albeit it was #41 at that time), I clecoed everything to the bottom skin (to straighten all the parts) to see if the holes align.

It seems that the holes were good, so I upsized them to #30.

Finally, I drilled F-728B to its corresponding part, the F-728A bellcrank channel.