Seat back brace 2h

2h

November 4, 2022

Today I continued working on the seats.

The first thing was to cut aluminum angles. Not too exciting, but needs to be done! I am still waiting for the angles from Aircraft Spruce, so I only did the horizontal ones (parts F-637C).

I need to round the corners of two of the angles, so they sit flat to the seat back. I am going to try to use a wooden router with a roundover bit. I tried on a scrap piece, and it is ... doable. It does require some thoroughness: there is a risk of the tool grabbing the angle and throwing it away.

I can probably do it on a mill, too, but since the table of my mill is too short, I will have to move the part multiple times, which would cause some discrepancy in the rounded corner (not that it matters, though).

I should have rounded the corners first because then I wouldn't have had to start the rounding from the very edge. The tricky thing here is feeding the end of the angle in the tool is dangerous: there is a risk of feeding it at the wrong angle such that the tool will grab. Feeding it from the middle in the reverse direction is dangerous because it will be "climb milling", which also tends to grab the part. However, with a very small feed, it is manageable. Or I can turn the angle around and finish at that edge rather than start at it.

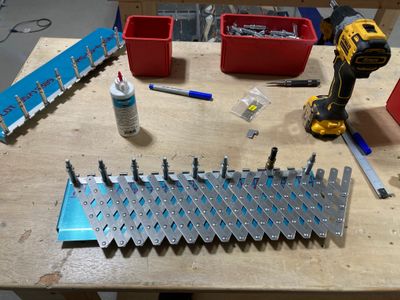

Then I cut the hinges for the seat back brace and drilled them to the brace itself. I used my rivet fan to locate the holes. I drilled directly through the fan as it works better that way.

Drilled the holes to the final size.

And trimmed the brace. Now I need to deburr the part and cut the lightning holes, which I will try to cut with the hole saw. Or not -- they are optional, after all.