Riveted F-704 1.5h

1.5h

December 28, 2022

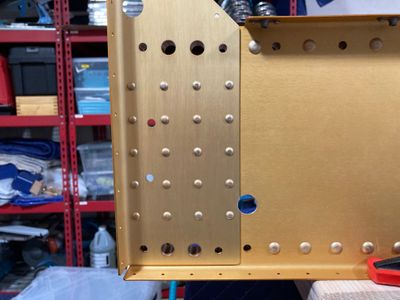

Riveted sides to the F-704 central section.

Just a short session. First, I riveted the sides to the F-704 central section. I set two outermost rows of rivets with the squeezer. The two innermost rows I bucked. At first, I started with my tungsten bucking bar, but its weight wasn't quite enough -- it was jumping a lot. And I wanted to increase the pressure even more to reduce the "mushrooming" of the shop heads. So I switched to my heavy 5-lb bucking bar (which I primarily use for back-riveting), which worked much better. Very solid and easy to hold straight.

I still managed to get few "smileys" when I was holding the rivet gun with my left hand. The most annoying were two last rivets. I got "smileys", drilled them out, then got both of them "smiley" again! The good thing is that I had plastic cap on the gun, and anodized parts have a hard "shell", so no marks on the part. Also, drilling the rivets was easy, no damage to the holes, so all is good.

Sides riveted. Also, I relieved side sections a bit to fit the bushings (after consulting with Vans' Builders Support).

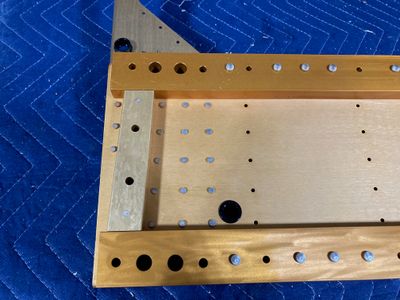

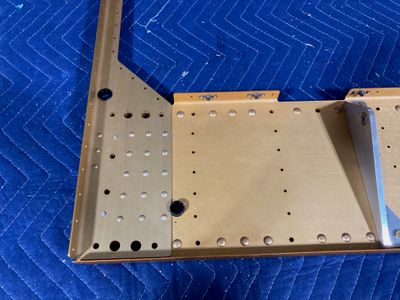

Riveted the bars to the aft sections, too.

And put the bushing. Even though I might remove them later, installing a bushing gives me satisfaction. I was debating which direction do I want to install it and decided to install it reversed. Trimming would be an option, but it's just too much work. Plus, there is a risk that after trimming it will not cover all the edges.

Finally, I spent some time on the control column brass bushings to remove the binding I was getting. I got my 3/8" reamer, but it turned out that the reamer fits just fine through the holes in the control sticks. So I resorted to the second option of relieving the center of brass bushings a bit. I used the wear pattern to see where to sand (the wear pattern formed after installing the bushing and moving the stick couple of times).

Same control sticks, but they are not binding anymore!