Some setbacks 1h

1h

January 6, 2023

Today was a day of disappointment.

The first setback was the tail spring. Even though the description said it is a direct replacement for Van's tail spring, I asked FlyBoy Accessories if there are any differences. Blake responded and said that it is done to the same standards, but Vans' changed the diameter of a thin end from 0.635" to 0.644".

This potentially means that the tail wheel I want (JD Air one) would not fit well. I asked JD Air what is the diameter of the hole in their yoke, and Darwin replied that indeed they have 0.643"-0.645". Bummer.

Well, the plan B is to use the original parts, after all. I still haven't received them. I sent Van's an e-mail asking if I can get at least some back-ordered parts (seems like the whole tailwheel assembly is "limited stock available").

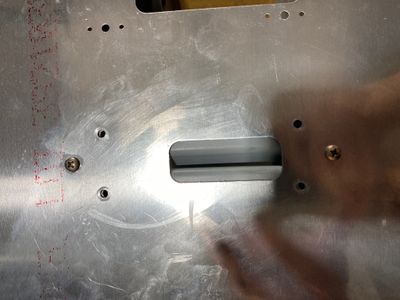

The second issue I found after I clecoed the F-770 forward side skins. The skins are not "tight" in the area around the F-715 seat ribs -- the ribs are not "bulging" enough, I think. Here is what it looks like from the side of the holes in the flanges:

You can see that the holes are too close to the rib web. I am going to try a new set of ribs to see if I can make them better. With the current parts, I think I can pull the skin to the ribs, but it might get a bit wavy on the bottom of the skin.

The third issue I found once I tried to screw the floors. It turned out that my crotch strap nutplate holes are way off. I don't know how did I manage to drill them that badly. I checked the log entry -- and I think I clecoed skins and the removable floors, but, apparently, this was not enough (probably, should have clecoed fixed floors as well). The holes are off left-to-right which I cannot really adjust.

The good thing is that all other holes on the floors aligned well with existing parts, so I only need to fix the crotch straps. There are two options. Option #1 would be to replace the straps. However, drilling them out might be a bit of an issue. Option #2 would be to remove nutplates from them, then rivet a backing plate to the "lips", re-drill for the correct location, then rivet the new nutplates.

I think I am going with option #1 as it looks cleaner to me. I was not fully happy with how I riveted them anyway (some rivets are not very tight).