Dropped the sump on the engine 2h

2h

January 22, 2023

Few more disassembly steps for the engine.

Today I removed the oil sump and looked at a few things.

There were a couple of small items I noticed while dropping the sump. First, the fasteners were not 100% consistent. A few nuts missed a washer (they only had a lock washer), and one bolt had two washers for some reason (seemingly, without any need for that). It's nothing, of course, but might be telling a bit about the attention to the details of the builder.

Also, one bolt on the bottom is installed "reverse" (from what I understand, the convention is to insert bolts from the left when an engine is vertically on the stand). Could be done for clearance reasons, however, I don't know.

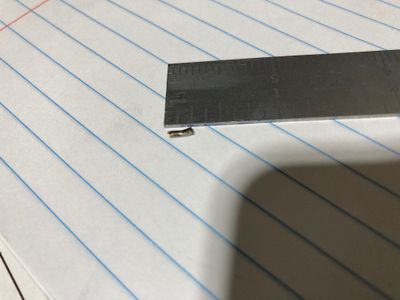

A bit more interesting was a small piece of metal I found in the sump. Looks like a piece of a cotter pin to me. However, it could have been dropped there after the engine was removed. Seems like these can drop from magnetos.

Then there was a bigger issue. Early on I noticed that the plug on the sump is all covered with RTV. So I thought that it was leaking, and that was the "fix".

Here you can see the plug.

Also, before removing the plug I noticed a PTFE tape on the plug.

The plug was put really, really tight. With the help of a torch, I was able to remove it, and sure enough, there was an issue. Somebody cross-threaded the plug and damaged the threads in the sump.

I cannot think of a good reason why anybody would ever remove that plug. It seems like it is usually used for an inverted oil installation, but otherwise, it is installed once and is never removed. Did the original builder damage the threads? Who knows!

Either way, I need to find out how to repair it. I asked DivCo, Inc., who are specializing in crankcase repairs (they also do accessory cases and sumps) if they can repair it and how much it will be.

Alternatively, I am considering bringing it to a local car shop that can TIG weld the hole, and I can make a new hole with the 1/2" NPT pipe threads in it. Assuming this is a typical aluminum weld job.

And yet another tiny little thing was a loose nut on cylinder #1 (the small one). It was pretty much finger-tight. I was checking the size of the nut, put my wrench on it, and it turned without any effort from me. Will see if there are any other loose cylinder nuts!

Then I removed the accessory case cover and realized that without the gears, it won't be easy to put the pistons into the correct positions (I haven't removed the cylinders yet -- waiting for a spark plug socket). So I put it back temporarily. And removed the cylinder covers instead. Not much else to remove, but I found that the thrust buttons were broken the cylinder #1.

I guess, it just happens over time.

These were my findings for today. So far so good, the damaged hole is hopefully not a big issue.