Fabricating the rudder stops 3h

3h

September 10, 2023

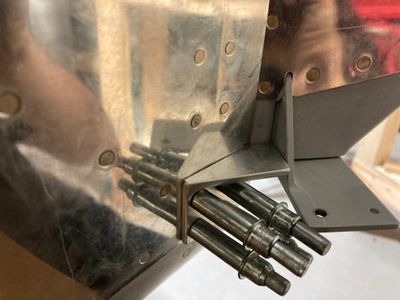

While waiting for my fiberglass supplies, I fabricated new rudder stops.

The issue with the stops fabricated per plans is that they are too small. Also, the location of the bottom aft hole gives a very small edge distance on the F-712 bulkhead flange.

So, I ordered a new angle and cut a slightly bigger piece. At first, I only drilled the bottom front hole, then used a cleco clamp to locate the hole. It's not a precise way by any means, but all I wanted was to get in a ballpark.

Then I drilled the hole (I'm using left and right rudder stop photos interchangeably). The edge distance looks good.

After that -- the two remaining holes. I placed them per plans, but would be a bit better to place them just a little bit higher, for a better edge distance on the internal flange of F-712.

Then I simply filed and sanded the stop until I got to the point where rudder deflection was according to the plans (1-1/8" from the elevator in a neutral position).

The stop on the other side.

The distance to the elevator.

In total, it took me probably 2.5 hours to make the first one, with all the sanding and filing. Also, at first, I drilled the holes per plans and then realized that the bottom aft hole wouldn't get enough edge distance on the upper edge. The second rudder stop, the right one, took only half an hour because I used the left one as a template.