Cleaning the parts 2h

2h

May 16, 2022

Did a tiny bit of work, mostly cleaning all the parts with the EkoClean.

Today I finished deburring the skins with my Aircat die grinder. I used roloc attachment and blue Scotch-Brite discs ("very fine"). This tool is an air hog! The compressor I have gives 5.3 CFM at 90 psi, and it wasn't anywhere what the tool wanted (I saw some numbers saying it needs 7.8 CFM at 90 PSI).

Then I took my cleaning supplies and washed all the parts (except the skins) with the EkoClean. It wasn't really necessary, you can do that step just before the etching, but I did not want to contaminate the EkoEtch with the EkoClean if I constantly switch between these two.

One thing I noticed is that parts become "squeaky" after the cleaning with the EkoClean, but still would not pass the "water-break" test. I suppose the role of cleaning is to remove heavy contaminants and grease -- etching and scrubbing should remove the rest.

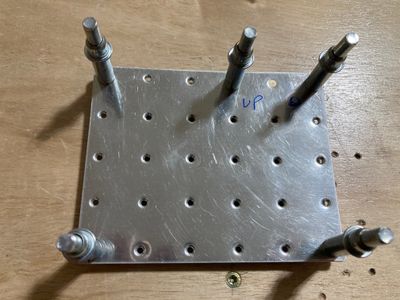

Finally, I made a small coupon to train my flat riveting skills.