Priming the skins and the spars 5h

5h

May 17, 2022

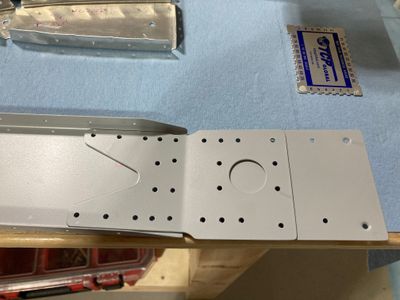

Today I started priming horizontal stabilizer parts.

Okay, this priming session did not go as smoothly as the previous one. First, I misconfigured my paint gun. I used 25 PSI, which, I think, turned out to be a bit too much (I turned it down to ~20 PSI later). Or maybe I was spraying too close to the parts.

The bigger issue, though, was that I sprayed way too much of the primer! My initial mix was about ~131 grams total. I started spraying, and it did not look too bad until I ran out of the primer while still priming the first skin! At this moment I have realized that maybe I am putting too much of the primer.

So I reduced the primer flow a bit and mixed the next batch of ~280 grams. This one was enough to prime the remaining skin, all the long pieces (spars), and a few more. This still sounds like a lot of the primer, but instructions do require a fairly thick coat of 3 mils. Also, some amount from the first batch probably was stuck in the gun and the mixing bucket, hence the high usage. Or at least this is what I tell myself.

It did not leave streaks on the large areas of the skin, though, and dried pretty quickly, so maybe it was not that much thicker than needed.

I did get a lot of primer streaks this time, though, but primarily because parts were long, and they were hanging high in my paint booth. So when I started spraying, I would start on the part itself instead of starting the spray outside of the part and then moving across. I am still learning how to control the spray gun.

I sanded streaks where it would interfere with other parts (ribs), but otherwise, I am not going to do anything else. Should be good enough for protecting the insides and next time I will do better!

The hole is not as bad as it looks in the photo -- it is mostly a shadow created by the primer blob.

The bigger issue was that I did not notice that I still have water in the holes of the long aluminum bars. It was getting late so I did not want to wait for another hour for parts to completely dry. I blew them with the hot air gun, but, apparently, not enough.

Debating if I should redo the part or not, I decided to wait for the streak to dry, and then I just painted it over with the brush using the leftover primer. It kind of looks okay in the end. After several hours (which, in my understanding, is not even enough for EkoPoxy to fully cure), I tried to peel it with the aluminum duct tape, and it did not lift anything.

My reasoning for doing this was, first, that it is less likely for me to ruin the part. Second, even if the primer peels off in the end, it wouldn't be the end of the world.

Also, every time I had a concern that I am spraying way too much of the primer, I would spray it on my test coupon and use a paint gauge. It would show 2-3 mil, which is what I am supposed to spray. Besides, in my first session, I definitely had a case of spraying too little such that the aluminum would show through the primer. Maybe, I need to try a smaller nozzle (1.4mm) and try to spray a thinner, but more uniform layer?