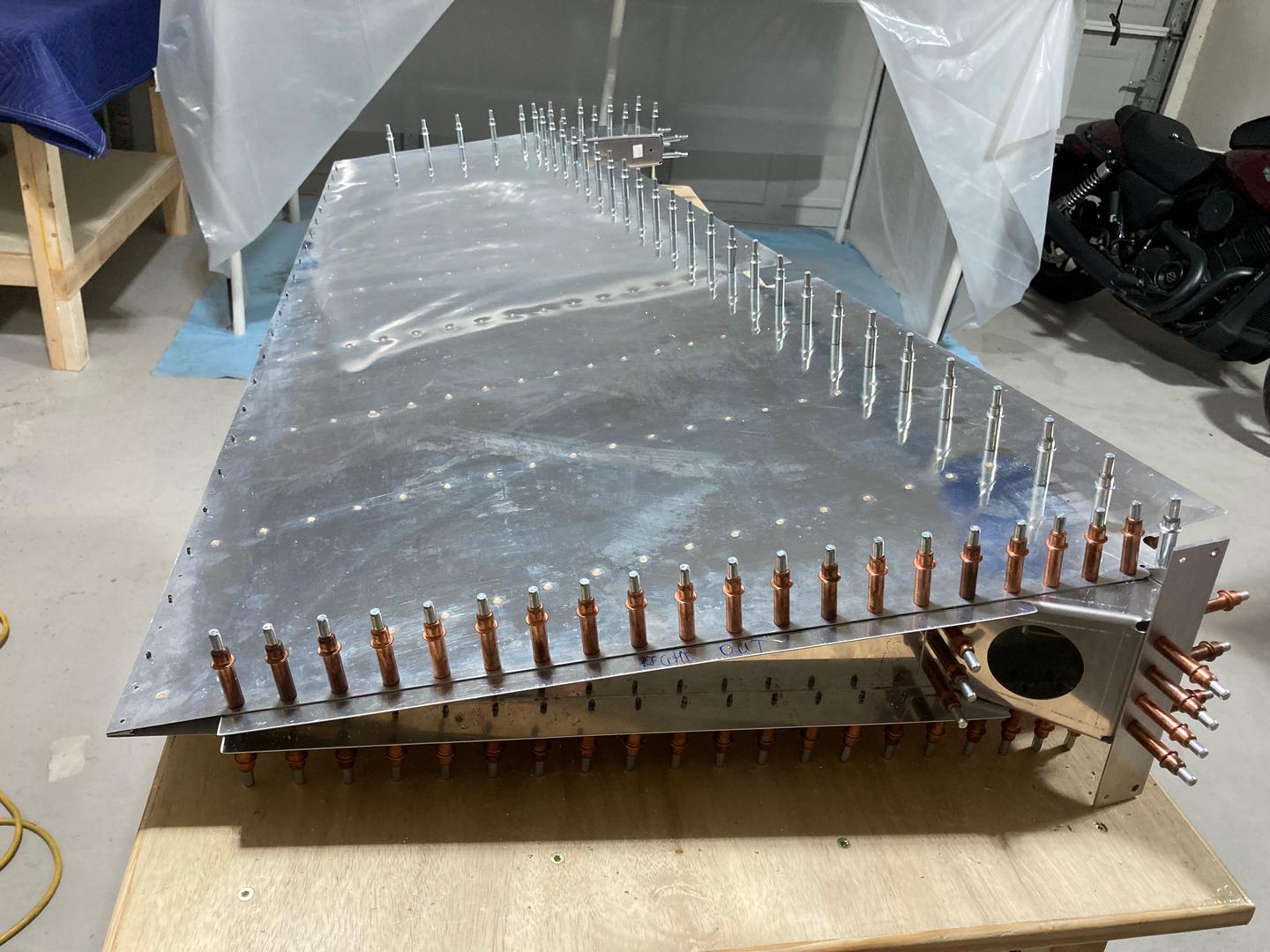

Continuing the rudder build 3h

3h

June 28, 2025

So I got okayed on my plan to upsize rivets to #30.

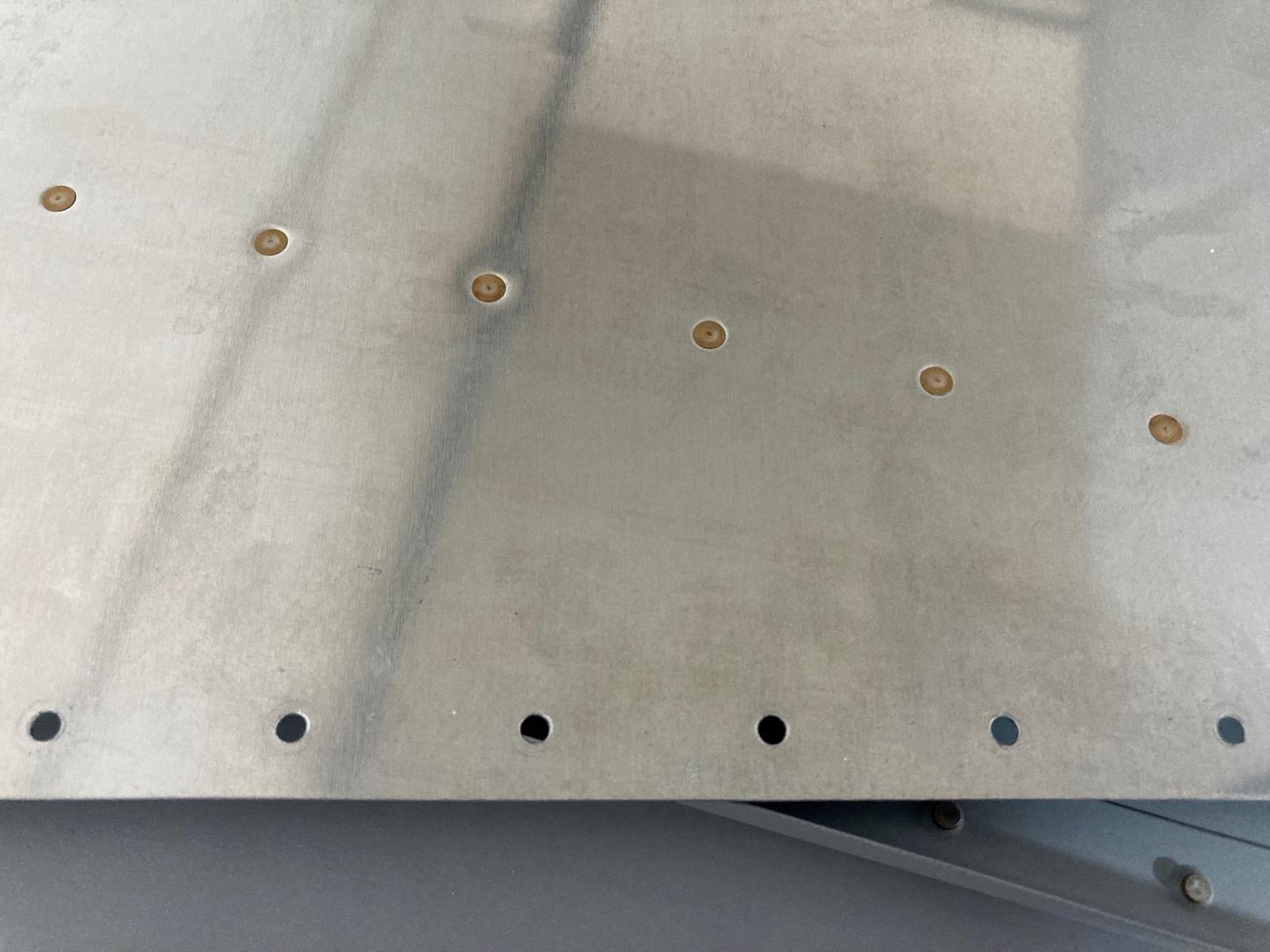

The answer was that upsizing is okay, but I should not expect to get away with that type of work in the future. I'll try to remember that lesson. So I drilled the whole row to #30, removed the clecoes, and...

...all the holes look good! They are round, and the edge distances are good also.

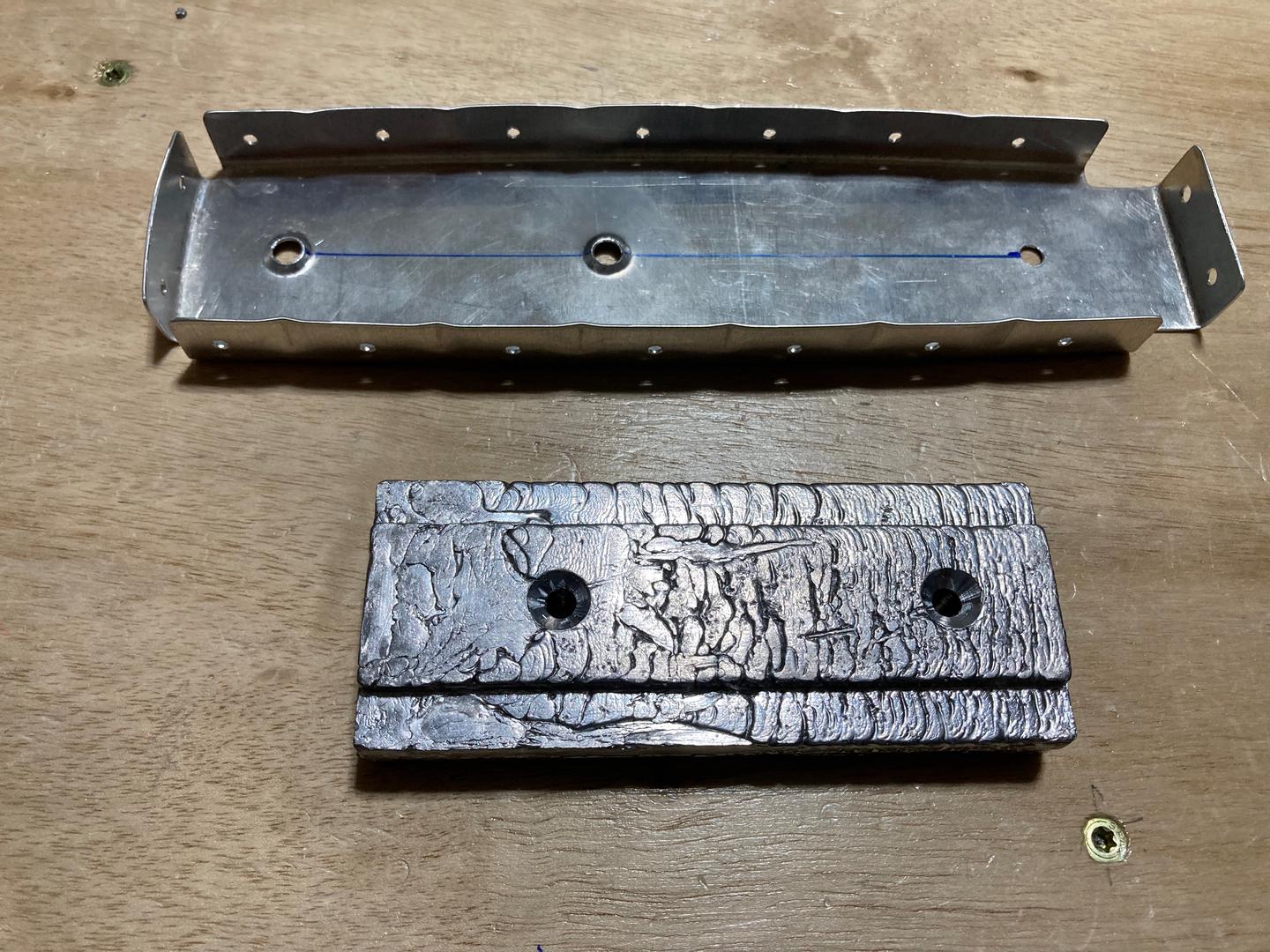

Then I moved to the counterbalance weight. I drilled the hole for the screw (using a #12 drill bit), then dimpled the counterbalance rib and counter-sunk the lead weight. I used a manual deburring tool with the countersinking bit installed. The lead is so soft that a couple of turns is all you need. I counter-sunk until the weight sits flat to the rib.

I will use a fuel tank sealant ("Pro-Seal") to attach the lead to the rib.

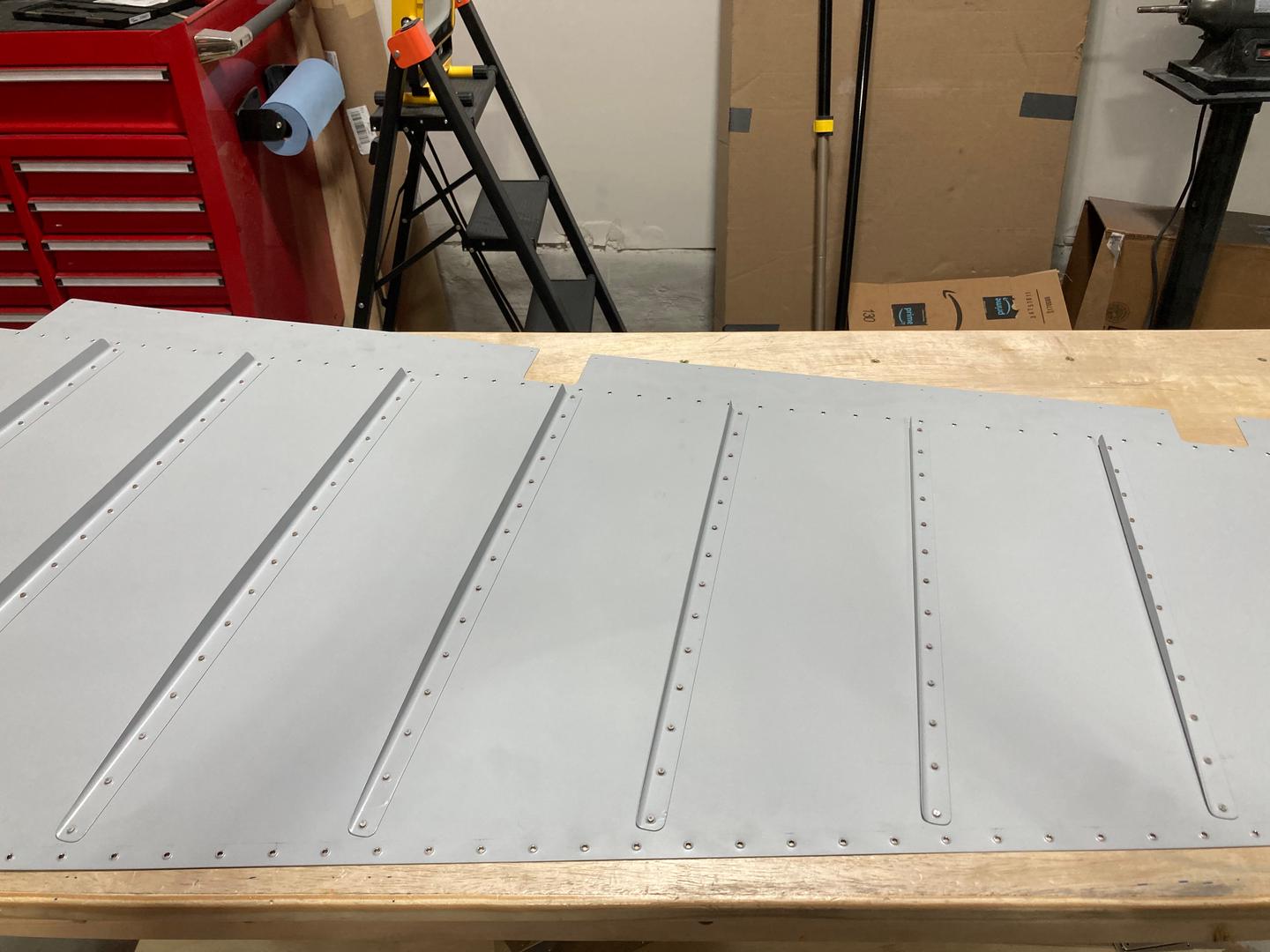

Then I dimpled the skins since I had primed them already.

Also, while I had some time, I started deburring the elevators stiffeners on my Scotch-Brite wheel. There is something aesthetically pleasing about turning all those ugly edges into nice, smooth ones.