Rolling the right elevator leading edge 3h

3h

July 13, 2022

Today I rolled the right elevator leading edge.

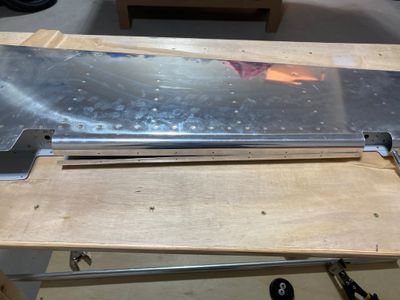

I used a simple fixture: two J-bolts (made from HomeDepot U-bolts) and a 3/4" EMT conduit. I keep the conduit tight to the table and tape the leading edge to it, then roll.

The first segment turned out pretty well: the edges are tight. There is some amount of force required to align them, but not too much.

This is how I attach the Gorilla tape.

Not much difficulty with the middle segment as well. However, it required a bit of massaging to get it tight.

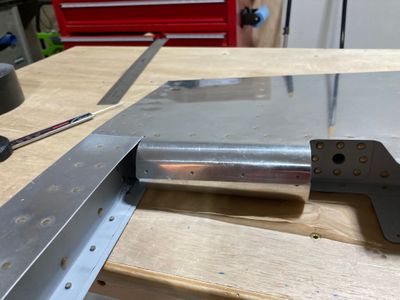

The last segment (the inboard one) is where I started getting issues. First, the elevator horn got in the way.

I did not want to disassemble the fixture, so I just cut the pipe in place (I wouldn't be able to use the full pipe anyway, as it will not fit between the counterbalance arm and the horn).

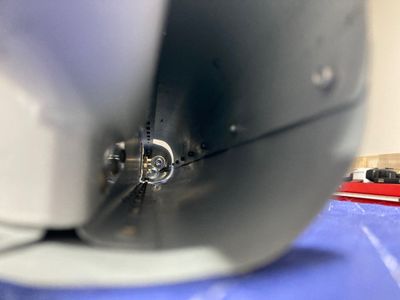

Then I spent a lot of time trying to massage the edges so they overlap relatively well. The issue seemed to be that I rolled the outermost part too much and I did not roll the innermost part enough (because the pipe got too close to the part). Not sure how to do it better next time. Maybe, use a smaller conduit closer to the spar?

After drilling the holes and installing the rivets, this is what the inside looks like. The inner edge is not perfect, but it should do.