Drilling the center section and F-623 ribs 5h

5h

October 15, 2022

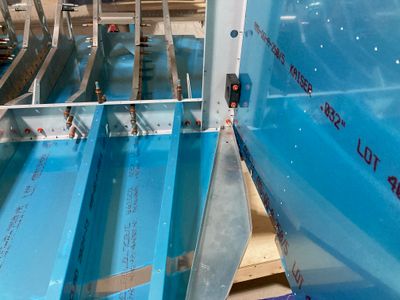

More work on the center section: drilling to the skin and fitting F-623 ribs.

First, I drilled all the holes from the skin to the ribs (except for the aft two rows). I know, you cannot tell a difference since everything is clecoed all the same!

I haven't inspected the holes, but I have a suspicion that I elongated one of the holes through the center section bar of the F-705 bulkhead. Not much, but it seems to be around ~0.140", which is more than the acceptable 0.135". I ordered some NAS1242 repair rivets (which are 9/64" shank, but with the AN470 head) which I will use for the repair.

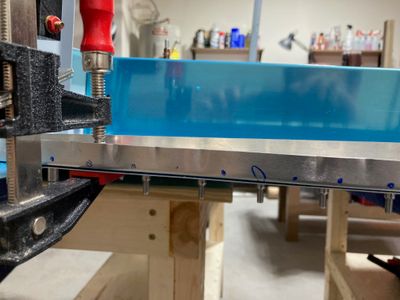

Then I started fitting the F-623 ribs. Due to the curvature of the front part of the rib, it needs some fluting. To flute it, I needed to know where are the holes from the skins so I know where I can flute. To find that, I temporarily clecoed the side skin and marked the location of the holes.

Then I fitted the ribs. In the end, I fitted the rib in a way to locate the holes about the same distance from the rib flanges. This gave a good fit on the forward part, which is important because this is where two skins are coming at the 90-degree angle. On the aft side, however, one of the ribs is a bit inside.

I don't think this is going to be an issue since at that location the side skin curves and this curve will extend beyond the F-623 side ribs.

Finally, I drilled the ribs to the skins.

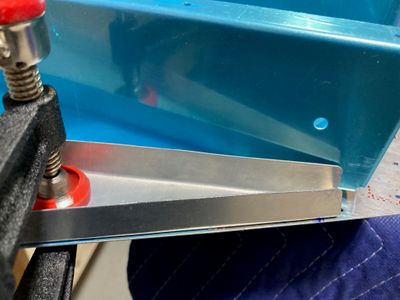

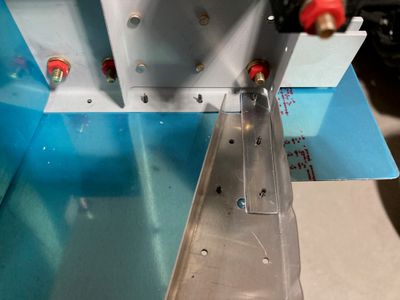

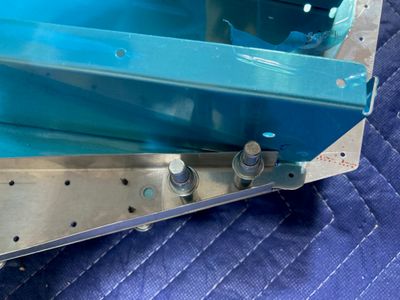

After that, I made attach straps for the ribs. I modified the forward attach strips, so they don't encroach on a neighbor rivet. I saw some folks would make the part larger to include four rivets on the rib side. However, the plans show three rivets (two to the F-623 corner ribs and one to the F-705 bulkhead), so I decided to make the part a bit narrower instead.

Then I made two aft attach strips. I, same as some other builders, did not like the design from the plans because it gives a very short edge distance. Therefore, I modified it to add a bit of "meat" to the strap, which took me a couple of iterations (I think, I was too tired to work -- should have stopped earlier!).

Both straps clecoed.

Later I thought that maybe I shouldn't have drilled the straps as these holes should be drilled in assembly with the aft section of the fuselage. Also, the corner ribs themselves could probably be fitted better when the forward side skins F-770 are fitted. Too late now. So far most of the pre-punched holes matched pretty well, so these probably would match well, too.

Still thinking if I want to rivet the center section without the F-704 bulkhead. I think dimpling should not be an issue -- I can dimple the C-Frame style, with the hammer. I probably will have to drill and dimple the holes that attach the seat ribs flanges, though, because I won't be able to dimple those well.