Longerons and the side skin 3h

3h

February 12, 2023

Prepared the longerons and bend the left skin.

First thing I did I put longerons side-by-side to the fuselage with the F-770 skins installed and marked the location of the notches for the F-711C bars. Then I drilled the holes at the end of the notch. Since the radius is specified as 3/32", and the width of the hole is 3/16", one 3/16" hole is all I needed!

I used my thin kerf saw to remove the material, then used the files to clean the hole.

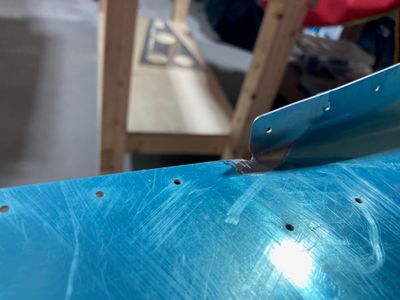

After that, I moved on to the F-770 skin work. The aft lower edge of the skin needs to be bent to create a rounded edge. I pretty much followed the instructions. First, I worked on a relief at the fore of the bend, where the skin has a sharp 90° bend. I used a file to open the hole a bit, then I sanded it with the #400 and the #600 grit sandpaper. I rounded the edge of the skin, too. This all is needed to reduce the chance of a crack forming at that location.

Then I did the bend. I didn't take a photo, but first I used a wooden block. The idea was that the wooden block would allow a slightly smoother corner than the aluminum angle. Then I switched to the aluminum angle since the wood was too thick to allow me to bend over 90° degree (to account for the spring back).

The "tight" corner looks good, and I don't see any cracking!

Overall, it turned out to be easier than I thought.

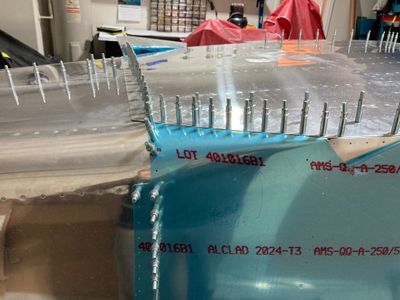

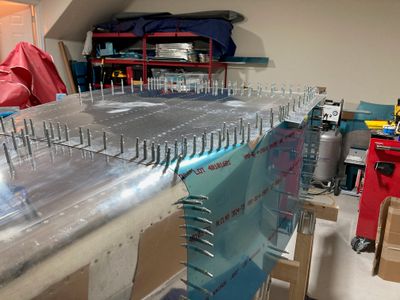

Then I clecoed the skin to the fuselage. At first, it did not look like it would fit at all. The aft hole on the bend was nowhere close to where it should be. However, working the clecoes both from the fore of the bend and from the top (from the longeron location) did the trick: skin slowly pulled into where it should be. In the end, it was even less painful than the F-711 bulkhead of the aft fuselage!

Since I got too stressed over that bend, I called it a day!