Continuing work on the upper forward fuselage 4h

4h

November 22, 2025

Today I continued working on the upper forward fuselage.

For the instruments, I want to install an Aerosport Carbon Fiber panel. I bought it now just so I can plan how much avionics I can install. I am a bit too ambitious about how much I want to fit in the panel. We'll see if I can make it work.

This is what my ambitions look like.

Two large G3x screens, and an avionics stack, top to bottom:

- Autopilot

- Audio panel

- Navigator

- Comm radio

- Backup G5 instrument

- Possibly, an SDS EFI programmer in 3-1/8" instrument size

The placement is primarily designed to work around space limitations in the slider configuration. In the slider, there is a central rib that goes all the way to the panel. A lower portion of that rib protrudes into the stack area, like this:

However, the Aerosport panel offsets the central stack about 1-1/8", which is approximately the depth of the autopilot rack (it is 1.150", but it can protrude past the panel). So it seems like everything should work.

The next equipment is an audio panel, which is not too long, so it doesn't hit the same central rib. I think it should clear it, but I haven't verified that yet. Then comes the longest item of them all: the navigator. It will require a hole cut through the subpanel. Then the radio, which I think will still require a hole in the subpanel, at least for the connectors.

By my estimates, the radio should still be above the bottom edge of the subpanel, so I will need to cut a square hole through the subpanel and keep the bottom flange (which I will reinforce with an angle).

Finally, the last two items should fit between the panel and the subpanel.

Back to panel installation. On both sides, the panel is attached to the structure via some fabricated angles.

While fitting everything, I found that the forward hole in my F-7108B doesn't match the hole in the firewall angle. I drilled this hole with everything but the skin attached. I guess the skin makes some difference in how the rib is positioned. It was still possible to install a rivet if I pressed on the firewall angle enough, but I decided that I don't want any extra stress there.

This was actually a third angle. I don't remember what was wrong with the first one, but the second one had incorrect hole placement -- I centered them, but the plans actually show holes centered on the "inside" part of the leg (7/16" distance instead of 3/8").

So I had to make one more. This time, since I already had the hole drilled in the firewall angle, I drilled the hole from the bottom.

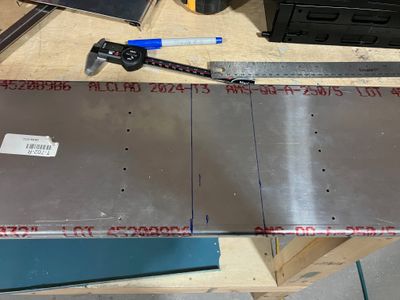

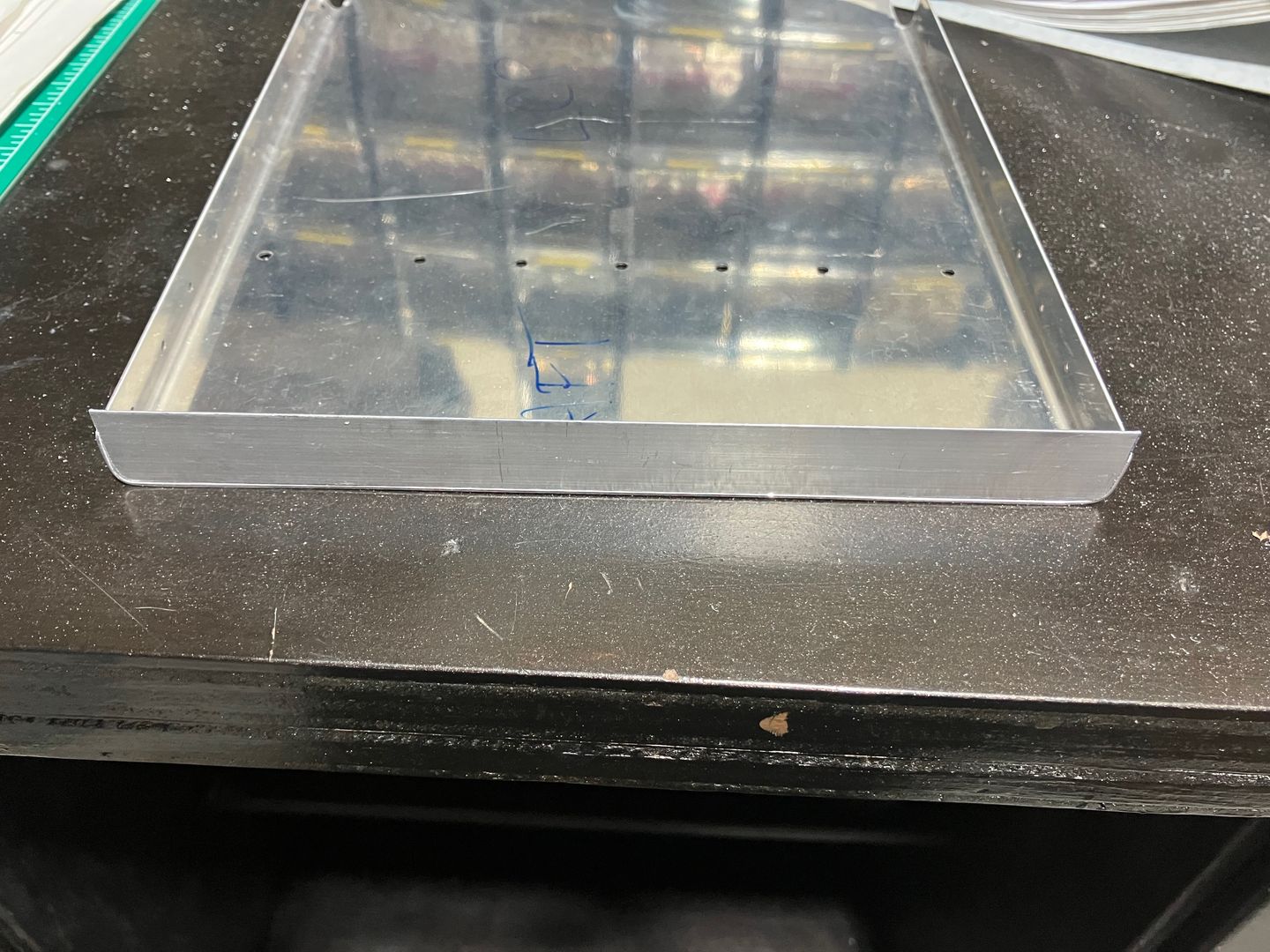

To support the radio stack in the middle, I want to create two "ribs" that will go between the subpanel and the panel frame. I wanted to use a flat sheet of 0.032" 2024-T3, but instead decided to use my scrap LCP (laser-cut part) tank baffles. I figured that the extra flanges won't hurt and will make the structure more rigid.

To attach these ribs to the subpanel, I intend to rivet an angle to them.

This angle will have some amount of screws to attach them to the nutplates in the subpanel. This way these ribs could be removed and rebuilt for a different arrangement of equipment.

Finally, I match-drilled all the skin holes to the ribs.