Riveting aileron fairings and flap braces 3h

3h

September 16, 2025

Today I riveted the aileron fairings and the flap braces.

I started by match-drilling everything to the skins and to the rear spar. And I immediately made a mistake reaming the holes for the skin -- instead of using #40 reamer, I reached for #30. I realized my mistake before I upsized the hole fully, but it was already slightly bigger than #40. So I upsized it to #35, then used my NAS1241AD3 rivet.

The rest of the riveting process went without any issues, both of the aileron fairings and both of the flap braces are riveted to the wings.

After that, I temporarily installed the ailerons.

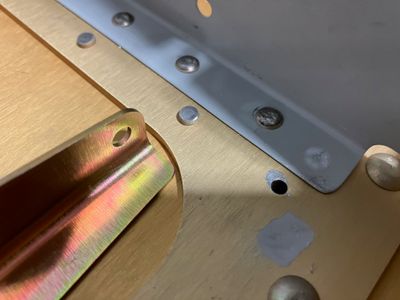

While working on the braces, I looked closer at one of the rivets that attaches the leading edge, and I didn't like it at all. I knew it wasn't perfect, but by being able to look very close at it, I noticed that it actually cracked a little bit.

So I drilled it out. Since the factory head was inside the leading edge, I had to drill it from the back. Since the rivet was skewed, I used other rivets to find the center. I managed to remove the shop end without enlarging the hole, then I pushed the rivet into the leading edge. Getting the factory head of the rivet I drilled out was a challenge, but luckily, my wife was able to reach it through the lightening holes!

Then I installed a Cherry Max pull rivet in that location.

Nice and clean!